Steel sheets generally range in thickness from 1/16 inch to 3/16 inch, while steel plates include thicker products varying from 3/16 inch to a number of inches thick. Recognizing the residential properties, types, and applications of steel sheets and plates is essential for engineers, architects, and manufacturers who depend on these materials for their projects.

Among one of the most usual kinds of steel sheets is hot-rolled steel, which is generated by rolling steel at heats, making it much easier to develop and shape. This process not just produces a wide variety of measurements and thicknesses but also enables the manufacturing of larger sheets quickly and successfully. An additional prominent type is cold-rolled steel, which undergoes handling at space temperature, causing a smoother coating and enhanced mechanical residential or commercial properties. Cold-rolled steel sheets are frequently made use of in applications where accuracy and surface finish are critical, such as in appliances and auto elements. Additionally, there are specialized steel sheets, such as galvanized steel, covered with a layer of zinc to give improved rust resistance, making it suitable for outdoor applications, consisting of roof and siding.

Steel layers come in numerous grades, consisting of structural, aquatic, and abrasion-resistant, each with particular properties customized for different settings and tons. Architectural steel plates are utilized in the building and construction of bridges, buildings, and huge devices as a result of their stamina and durability. Marine-grade plates, on the various other hand, are designed to stand up to rust and deterioration when exposed to salt water, making them important in shipbuilding and overseas structures. Abrasion-resistant plates are used in environments where products are subjected to hefty wear, such as mining, building, and reusing procedures. The selection of the ideal grade and sort of steel sheet or plate is important for ensuring the safety and security, efficiency, and longevity of the last product.

The production of steel sheets and plates entails significant processes including cutting, flexing, welding, and ending up. Welding is an additional essential process in the assembly of steel structures, needing expertise of various welding strategies such as MIG, TIG, and stick welding. The finishing process may consist of surface area therapies and layers that enhance the material's resistance to rust, enhance looks, and lengthen solution life.

The use of steel sheets and plates has evolved with advances in modern technology, leading to technologies such as high-strength low-alloy steels, which give equal mechanical residential properties to typical qualities while minimizing weight. The consistent research study and development in the metallurgy of steel are concentrated on developing lighter, more powerful, and much more corrosion-resistant materials, which will better increase the adaptability and applications of steel sheets and plates in different markets.

Sustainability is an increasingly important factor to consider in the manufacturing and use steel sheets and plates. Steel recycling has been an integral component of the sector for decades, and most of brand-new steel generated comes from recycled materials. This procedure dramatically minimizes the carbon footprint related to steel manufacturing, assisting to deal with environmental problems. Makers are taking steps to optimize their procedures, lowering waste and power usage, aligning with worldwide sustainability goals. The ability to produce here high-quality steel while decreasing ecological effect not only benefits the earth yet likewise enhances the reputation of firms devoted to sustainable practices.

Steel plates serve as essential elements in bridge construction, with designers designing steel plate girders to sustain heavy tons and span lengthy distances. Furthermore, steel sheets are extensively utilized in erecting steel frameworks, providing versatility in design while making sure compliance with structure codes and safety requirements.

In the manufacturing market, steel sheets and plates develop the foundation of a significant variety of products. From home appliances to automobiles, the demand for reliable and long lasting products is critical. Automotive suppliers utilize high-strength steel sheets to generate body panels that are lightweight yet exceptionally sturdy, which contributes to boosted fuel effectiveness without giving up security. In a similar way, the appliance industry gain from cold-rolled sheets with boosted surface coatings, making certain aesthetic allure while providing lasting toughness against everyday deterioration. The combination of steel sheets in equipment and machinery not just boosts the functionality of products yet additionally extends their lifecycle, supplying substantial value to customers and manufacturers alike.

On an extra customized note, the oil and gas industry's demand for steel plates is driven by the construction of pipelines and storage facilities that should endure severe settings and stress. Steel plates made use of in these applications are often fabricated to exacting standards, ensuring they can withstand the rigors of transportation and storage of varied materials, consisting of unrefined oil and all-natural gas.

Past commercial applications, the visual use of steel sheets has actually discovered a home in building style. Modern design accepts technology and development, integrating steel sheets not only for structural stability however, for aesthetic influence. Steel can be adjusted to develop vibrant facades, roofing, and interior decoration components that commemorate the product's commercial heritage while using contemporary looks. Making use of corten steel, known for its rustic patina, is particularly preferred in producing outside sculptures and developing facades that mix right into natural environments, showcasing the versatility and elegance of steel in numerous layout approaches.

When it concerns selecting providers for steel sheets and plates, several variables need to be thought about to ensure your tasks continue smoothly. The reputation of the distributor, item range, top quality guarantee processes, preparation, and customer support are essential components in selecting a companion. Lots of fabricators additionally need particular qualifications, such as ISO 9001, to make sure that providers fulfill worldwide quality monitoring requirements. The schedule of value-added services, such as pre-fabrication and machining, can streamline job timelines, providing added value to home builders and producers.

As we look toward the future, the function of steel sheets and plates will likely pivot in feedback to emerging technologies and materials scientific research. The total trend toward modular building is most likely to more accentuate the significance of steel sheets and plates, as standard parts create effectiveness in setting up and reduce on-site construction time.

In conclusion, steel sheets and plates are important materials that form the foundation for numerous applications across a diverse range of industries. As industries make every effort for technology and ecological duty, the value of understanding and picking the proper steel sheets and plates will certainly stay critical to achieving functional, cost-effective, and sustainable design remedies.

Jennifer Grey Then & Now!

Jennifer Grey Then & Now! Danica McKellar Then & Now!

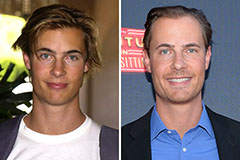

Danica McKellar Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!